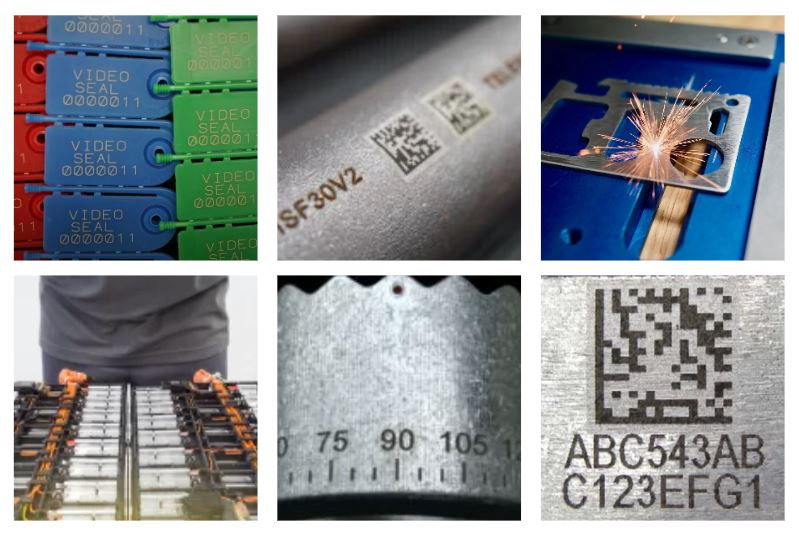

In industrial environments where traceability is essential, marking becomes an important stage of the production process. The need to record information in a permanently legible and consistent way about increasingly diverse materials requires technologies that combine precision, automation and operational stability.

That is why in the following article we will discuss the XpressMark fiber laser marking system. of Telesis.

Autofocus automation and dimensional control

The model XpressMark incorporates features that reduce manual intervention and improve process repeatability.

The AutoFocus system automatically adjusts the focal point on each part, ensuring the uniformity of the marking even when there are slight dimensional variations.

Complementarily, the Vari-Z technology allows working with different heights without the need to recalibrate the equipment.

These features are useful on mixed production lines, where components of different sizes or geometries are processed without interrupting the workflow.

Integrated vision and inline verification

For environments where traceability is a priority, XpressMark can incorporate an inline vision system that enables real-time reading and inspection of the marked codes.

This functionality ensures engraving quality, detects possible deviations and eliminates the need for a separate inspection system, reducing both the space required and the integration costs.

Optical performance and mechanical reliability

The unit uses a high-quality fiber source that provides a stable, uniform beam, capable of producing sharp marks even on small-format or high-density designs. The system can work on a wide range of materials, including aluminum, copper, stainless steel, brass, titanium and plastics, maintaining consistent engraving quality and a long laser lifetime.

Although it is the most affordable model within the fiber laser range, XpressMark delivers high-performance results at a competitive cost. The assembly is designed to withstand demanding industrial environments.

Easy integration and compatibility with industrial networks

XpressMark easily adapts to existing automation architectures. Its compatibility with standard communication protocols such as Ethernet/IP y Profinet, simplifying the connection to PLC controllers or MES systems.

Additionally, the optional Mark-On-thefly function enables marking moving parts, maintaining positional accuracy without stopping the production line.

The system is available in power ratings of 30 W, 50 W and 100 W, allowing it to be tuned to the material, line speed, or required engraving depth.

Industrial applications

- Automotive (metal parts, engine components, chassis)

- Aerospace (structural elements and machined components)

- Medical device manufacturing

- Construction and metallurgy

- Consumer products and advanced manufacturing

Demo at Advanced Manufacturing Madrid

We will be present with Telesis technology at Advanced Manufacturing Madrid on November 5–6 at IFEMA.

Our team will be available at stand 10I15, where visitors can watch real-time marking demonstrations.

📍 IFEMA Madrid – Stand 10I15

🗓️ November 5 and 6, 2025

👉 Get your free ticket