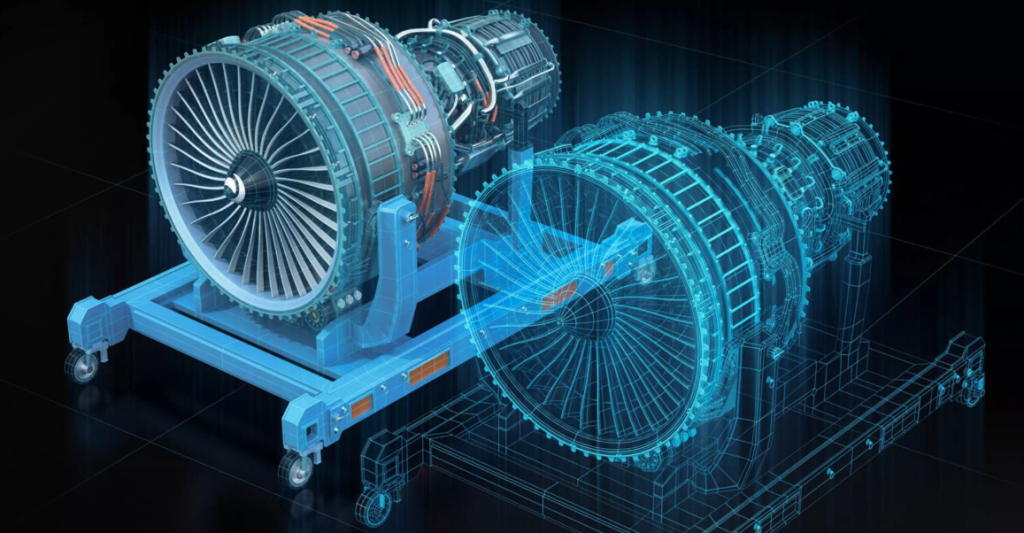

The digital twins allow virtually replicating machines, processes or entire plants, powered by real-time data. In the era of the Industry 4.0, these technologies are essential to drive efficiency, operational agility, and cost reduction.

What are digital twins in Industry 4.0?

A digital twin is a virtual replica that reflects a physical asset, system or process. It uses IoT sensors and historical data to simulate behaviors, perform predictive analyses and enable informed decision-making.

Digital twins are highly versatile, adapting from a complete plant to individual equipment. Their value lies in their ability to predict scenarios, improve designs and validate investments before implementing them.

Applications and benefits of digital twins in industrial automation

The digital twins are redefining how industrial companies design, operate and optimize their processes. Their ability to virtually and dynamically represent a production line or a specific piece of equipment allows them to offer tangible competitive advantages. Below, we explore in detail their main applications in industrial automation and the associated benefits.

Advanced simulation of industrial processes

One of the most powerful uses of digital twins is the production process simulation. Esta funcionalidad permite a los ingenieros recrear diferentes escenarios operativos en un entorno digital, lo que facilita el análisis de nuevas configuraciones, el rediseño de líneas de montaje o la evaluación de la viabilidad de incorporar nuevas tecnologías. Antes de ejecutar una modificación en planta, se pueden prever los efectos que tendría sobre el flujo de trabajo, los tiempos de ciclo, la eficiencia energética y el consumo de materiales. De esta forma, se minimizan los riesgos y se toma la mejor decisión basada en datos reales.

Real-time remote monitoring

In industrial environments where connectivity is key, digital twins act as platforms for remote monitoring. Al estar conectados a sensores IoT distribuidos en la planta, recopilan y visualizan datos en tiempo real sobre el estado de los equipos, temperaturas, vibraciones, consumo energético y otros parámetros críticos. Esta visibilidad remota no solo mejora la capacidad de respuesta ante incidencias, sino que también permite gestionar múltiples plantas desde un único centro de control, optimizando recursos humanos y tecnológicos.

Predictive maintenance and fault reduction

Another key application is the predictive maintenance. Gracias al análisis de datos históricos combinados con los inputs en tiempo real, el sistema puede anticipar cuándo es probable que se produzca un fallo en un componente o equipo. De este modo, se programan intervenciones preventivas en los momentos más adecuados, evitando paradas inesperadas de producción y extendiendo la vida útil de los activos. Esta estrategia reduce drásticamente los costes de mantenimiento correctivo y mejora la disponibilidad operativa de las instalaciones.

Continuous production optimization

Digital twins are also essential for identifying bottlenecks, inefficient processes or areas where productivity can be improved. By analyzing the full behavior of the production line under different conditions, parameters can be adjusted, tasks reorganized, or operation times reconfigured to maximize performance. This translates into a sustained increase in operational efficiency and a reduction of waste, essential factors for any industry that wants to stay competitive.

Training in safe and realistic environments

The virtual environment generated by digital twins is also used for the training of operators. Mediante simulaciones interactivas, los trabajadores pueden familiarizarse con el funcionamiento de la maquinaria, los protocolos de seguridad o los procedimientos de operación, sin necesidad de estar presentes físicamente en la planta ni correr riesgos reales. Este tipo de entrenamiento inmersivo mejora la retención del conocimiento y permite una preparación más completa ante situaciones de emergencia o cambios en los procesos.

Global benefits of applying digital twins in industrial automation

Implementing digital twins in industrial environments not only translates into targeted improvements but into a holistic transformation of how production is operated and managed:

Significant cost reduction: From savings on maintenance to energy optimization and planning improvements, digital twins have a direct impact on the profitability of industrial operations.

Greater efficiency and productivity: By reducing downtime, optimizing resource use, and speeding up decision-making, companies can increase total production with the same number of resources.

Improved final product quality: Early fault detection, fine-tuning of manufacturing parameters, and precise control of production conditions help maintain more consistent quality standards.

Enhanced safety: The ability to simulate risk scenarios, together with remote monitoring, helps prevent workplace accidents and ensure a safer working environment for all employees.

Digital twins are at the core of the industry of the future: they reduce risk, improve productivity, and are the key to a smart and sustainable factory.