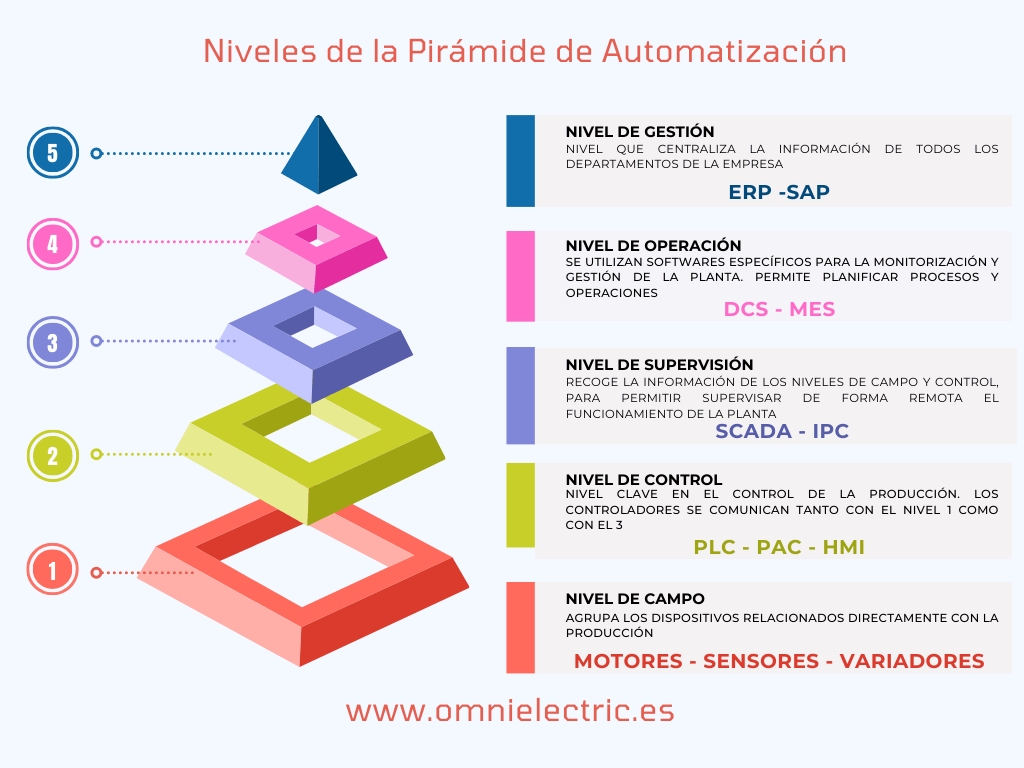

En Omnielectric, we understand the importance of automation in optimizing efficiency, safety, and productivity of industrial plants. The automation pyramid provides a visual scheme that facilitates understanding of how control and automation systems are integrated in an industrial plant. This hierarchical model highlights the function of each level and its contribution to the industrial environment. Below, we describe the different levels of the automation pyramid and how each plays a crucial role in the automation process.

Levels of the Automation Pyramid

Level 1: FIELD

At the base of the pyramid lie the physical devices present in the industry, such as actuators and sensors. These elements are fundamental for collecting process data and for real-time control of physical actions. Sensors gather essential data such as temperature, pressure, and speed, while actuators perform the necessary actions based on these data, such as opening a valve or starting a motor. This level is essential to obtain accurate environmental data and perform immediate actions.

Level 2: CONTROL

The next level includes control devices such as computers, PLCs (Programmable Logic Controllers) and PIDs (Proportional-Integral-Derivative Controllers). These devices supervise and control operations at the field level, processing data collected by sensors and making real-time decisions to keep the process in optimal conditions. PLCs are especially valuable for their ability to be programmed to perform specific tasks efficiently and reliably. This level acts as the brain of the system, analyzing data and controlling actions to ensure continuous and efficient operation.

Level 3: SUPERVISION

At the supervision level, SCADA systems are located. These systems enable comprehensive monitoring of processes and areas within an industrial facility. SCADA graphical interfaces facilitate monitoring the status of processes, receiving alarms, and making critical decisions. They also allow clear and detailed visualization of the entire operation, helping operators respond quickly to any anomaly. This level provides a global and centralized view, integrating data from the control level for efficient management.

Level 4: PLANNING

At this level are Manufacturing Execution Systems (MES), which focus on the planning and operational management of the industrial plant. Data collected from lower levels is used here to make strategic decisions, such as production scheduling, resource management, and preventive maintenance. MES ensures that all production processes are aligned with business objectives, optimizing efficiency and reducing downtime. This level transforms data into valuable information for production planning and optimization.

Level 5: MANAGEMENT

At the top of the pyramid are Enterprise Resource Planning (ERP) systems. These systems handle decision-making at a corporate level, covering all aspects of the business, from manufacturing to sales, purchasing, and finance. ERP integrates data from the entire organization, providing a unified view that aids strategic decision-making and optimization of business processes. This level ensures that the management of the company is coherent and efficient, aligning all levels of operation with the overall business strategy.

From its beginnings, automation has advanced significantly, integrating basic engineering with advanced technologies to meet the highest production demands. Although implementation may vary between companies, the automation pyramid provides a common framework to understand the integration of various technologies.

The automation pyramid is a theoretical-visual example that explains the five levels involved in an automation process and how all the technologies involved are integrated. It is read from the base to the top, considering all communications between different technologies. This structure helps companies maintain open and efficient processes, ensuring that all levels of the organization work together to optimize production and business management. At Omnielectric, we are committed to turning these principles into practice, providing comprehensive solutions that enhance performance and the competitiveness of our clients in the industrial sector.